Fill out your details for a free quote!

Average rating:

4.67 -

3

reviews

Get Automated – Cut Costs !

P.R.I was established to focus on providing automated production Lines for bakeries. The Company builds and renovates all sorts of unattended bakery equipment. The Company specializes in unique Mass-Production systems that can produce up to 20,000 pastries per hour, with minimum human attendance required. The development is personally adjusted and custom tailored to meet client’s demands and requirements.

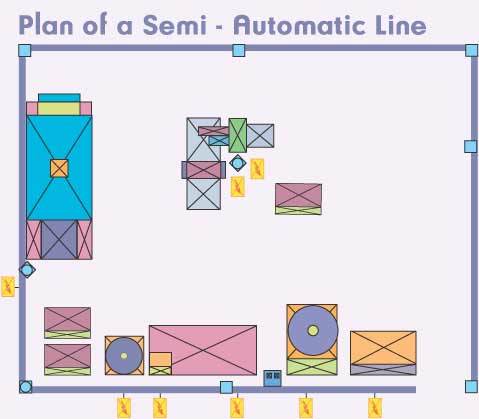

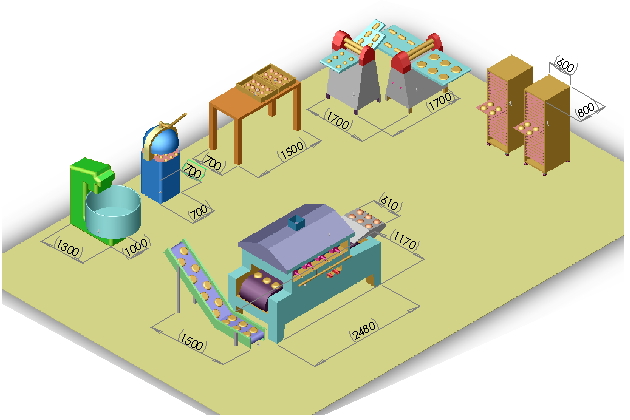

SEMI AUTOMATIC LINE

EQUIPMENT FOR SMALL BAKERIES, SUPERMARKETS AND RESTAURANTS FOR PRODUCTION UP TO 1500 PITTA BREED PER HOUR.

- Good for pizza, “samusak”, and all the pitta’s products.

- We supply new machines and recondition.

- Support in the bakery Designing.

- Support in the machine selection for the client needs.

- Instruction for the pitta baking.

- Supply of new machines and recondition.

- Trade-in possible.

THE SEMI AUTOMATIC LINE MACHINES:

(On the right)

DIESEL OIL TUNNEL OVEN

(A mini version of the Full Automatic oven)

Highly insulated. It’s covered with Stainless Steel (inside and out). The interior also has a partial cover of a stone construction.

The burner is placed in the back.

Includes an inlet machine.

GAS TUNNEL OVEN

Highly insulate and covered by Stainless Steel (inside and out).

The ceramic burner is placed on top and the pipe burner- blow.

Includes an inlet machine

ELECTRIC TUNNEL OVEN

Highly insulate and covered by Stainless Steel (inside and out).

The electric heating system is placed on top and blow.

Includes an inlet machine

(On the left)

FORK MIXER

160 kg capacity with a two speed motor.

DOUGH DEVIDER AND ROUNDER

Devides the dough and presses it. In its each pressing produces 30 perfectly round dough balls.

FLATTENING MACHINES AND CABINET

A set of flattening machines with two arms, adjustable for pitta size and thickness.

Inclues a mobile proofing cabinet with wooden trays for final proofing of the flattened dough.

SEMI AUTOMATIC LINE SCHEME: